Product details

In order to ensure the safe operation of the boiler and the safety of people's life and property, the design, manufacture, installation, use and maintenance of this series of boilers must strictly implement TSG G0001-2012 "Boiler Safety Technical Supervision Regulations" and JB/T10094 "General Technical Conditions for Industrial Boilers" ", GB1576-2008 "Industrial Boiler Water Quality", GB50273-2009 "Boiler Installation Engineering Construction and Acceptance Specifications", JB/T1612 "Boiler Hydraulic Test Technical Conditions" and other relevant national norms and standards.

In the field of thermal energy engineering in my country, due to the relatively high exhaust gas temperature of traditional boilers (250°C), the water vapor in the flue gas is in a superheated state (gaseous state), and it is impossible to condense into a liquid state and release the latent heat of vaporization, so the thermal efficiency of the boiler is calculated at the average time. The calculation is performed using the low calorific value of the fuel as the calculation reference. With the requirements of national energy conservation and emission reduction and the adjustment of energy structure in recent years, coal combustion is restricted in industrial boilers, and gas is promoted, especially the popularization and development of natural gas boilers with high hydrogen elements, and the exhaust gas temperature of boilers is getting lower and lower. . When the exhaust gas temperature of the boiler is low to a certain level (for example: <65°C (the saturation temperature corresponding to the partial pressure of water vapor in the flue gas of a natural gas boiler, that is, the dew point temperature of the flue gas)), the water in the flue gas is superheated. The steam will condense, releasing the latent heat of condensation. If it is used and the heat loss such as heat dissipation is very low, the thermal efficiency of the boiler will be improved by 5%-10%.

High-efficiency economizers and condensing heat exchangers are used to absorb the sensible heat in the exhaust smoke at the tail of the boiler and the latent heat released by the condensation of water vapor, so as to achieve the purpose of improving the thermal efficiency of the boiler. This boiler is a condensing waste heat recovery boiler.

Features1. The wet-back three-return structure is adopted, and the smoke pipe is symmetrical to the furnace axis and evenly distributed, which can improve the stress distribution of the tube sheet. The wet-back structure combustion chamber is completely immersed in water, the cooling condition is good, the rear tube sheet is not washed by high temperature flue gas, and the service life is long.

2. The application of corrugated furnace not only increases the heating surface, but also relieves the possible damage to the combustion chamber caused by thermal expansion and contraction, and improves the strength. The large furnace volume burns completely and fully saves fuel.

3. The front smoke box adopts hinged connection, which can be easily opened. Using high-quality sealing materials, smoke and heat insulation, not only reduces the temperature of the front panel, but also improves the thermal efficiency.

4. The large steam space makes the speed of steam out of the water surface low, and the built-in steam-water separation device ensures stable output of high-quality steam.

5. The threaded smoke pipe is used to enhance the heat exchange effect and improve the thermal efficiency.

6. The application of advanced digital control technology can accurately monitor the combustion process remotely. The strong current part of the control cabinet adopts ABB electrical appliances, with reliable quality ; the controller adopts LCD or touch screen controller, which has a high degree of automation, complete various protections, and realizes automatic control of water level and pressure.

7. A condensing heat exchanger is added at the flue gas outlet to reduce the exhaust gas temperature to absorb the sensible heat and latent heat in the flue gas, and improve the efficiency of the boiler (up to 95%).

Installation system diagram

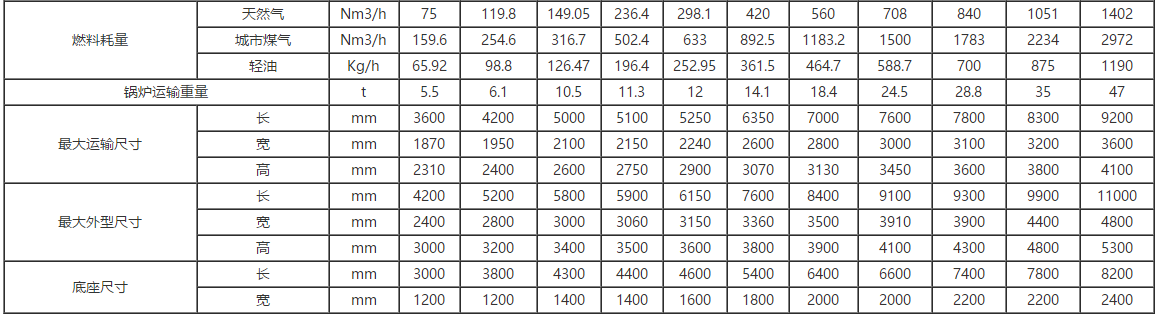

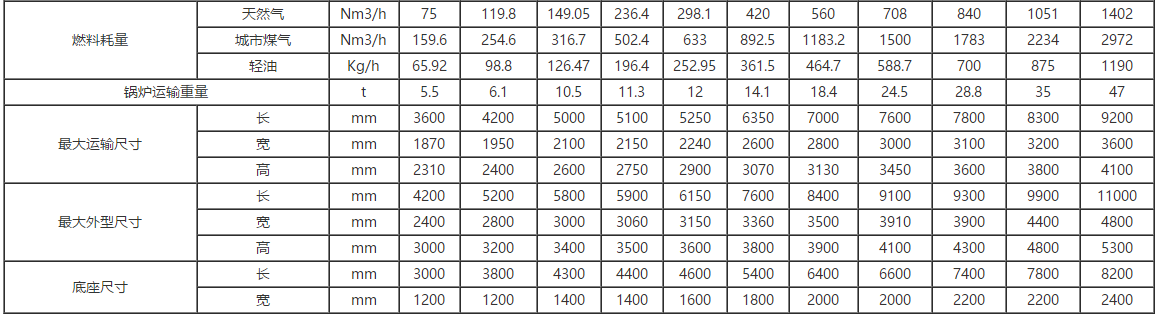

Product parameters

Remarks:

1. All the above values are based on the low calorific value of natural gas (LNG) 8,400kcal/Nm³, the low calorific value of city gas (CG) 4,000kcal/Nm³, the low calorific value of coke oven gas 4,200kcal/Nm³, the low calorific value of diesel 10,200kcal/kg and methanol low calorific value of 4650kcal/kg are standard calculations.

2. According to user needs, our company can provide other special types of boilers.