Product details

The body of the vacuum hot water boiler is divided into upper and lower parts. The lower part is a three-return flue tube shell type wet back structure, that is, the furnace and the flue form the heating surface. The fuel burns at a slight positive pressure in the furnace, and the high-temperature flue gas enters the first flue tube bundle through the return combustion chamber backwards along the furnace, turns 180° into the second tube bundle through the press-type front smoke box, and is discharged into the second tube bundle after convective heat exchange. atmosphere.

We use the design idea of the centrally symmetric three-pass structure to design a three-pass furnace body with a larger capacity. The biggest features of this structure boiler are: the central symmetry of the drum, the full wet back type, and the large inner tank and firebox. The structure is beneficial to provide enough radiation heating surface. The convection heating surface is composed of tube bundles of the second return and the third return. The front tube plate of the return combustion chamber is connected with the furnace, and the second return and third return smoke transfer chamber constitutes the front smoke box, and the temperature of the smoke is lower than 500 ℃. The temperature of the flue gas in the rear smoke box is lower than 150 ℃ after the three-return flue pipe fully absorbs heat, and then it is discharged into the atmosphere. The front and rear smoke boxes adopt a hinged light structure, which is convenient for opening and closing maintenance. The upper part is a vacuum chamber (negative pressure steam chamber), which is equipped with a tubular stainless steel steam-water heat exchanger to heat the circulating water flowing through the heat exchanger.

Features

1. The vacuum boiler operates in a vacuum negative pressure state, which is a boiler that will not explode and has good safety.

2. It operates in a vacuum state, with a low boiling point and heat exchange with latent heat of vaporization (latent heat of condensation), which effectively improves thermal efficiency.

3. A constant amount of heat medium water is stored in the furnace body, there is no danger of dry burning, no corrosion, no scaling, and long service life.

4. Built-in stainless steel or copper heat exchanger with special treatment, excellent heat exchange effect and fast heating.

5. Heat exchange is carried out in the boiler body, with high efficiency. The overall design is scientific, reasonable and compact, saving 50-70% of the floor space.

6. Users do not need to inspect and submit for approval according to the boiler and pressure vessel standards, which saves costs.

Control part touch screen display, virtual keys, Chinese and graphic display system working conditions, online operation guide, fault self-diagnosis. Fully automatic operation and manual operation can be used for one use and one ready to realize man-machine dialogue.

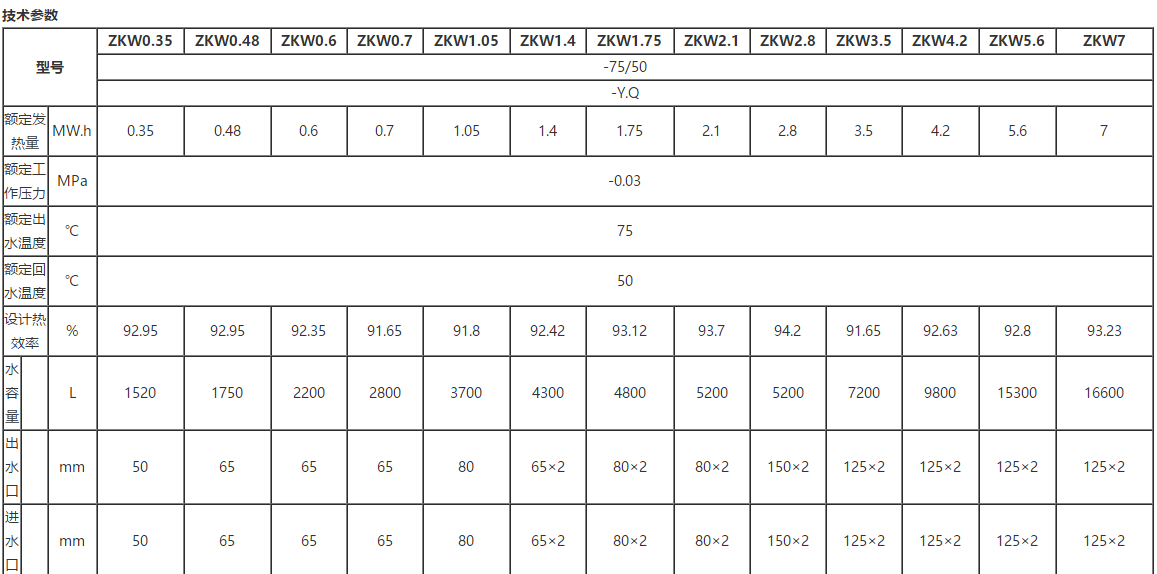

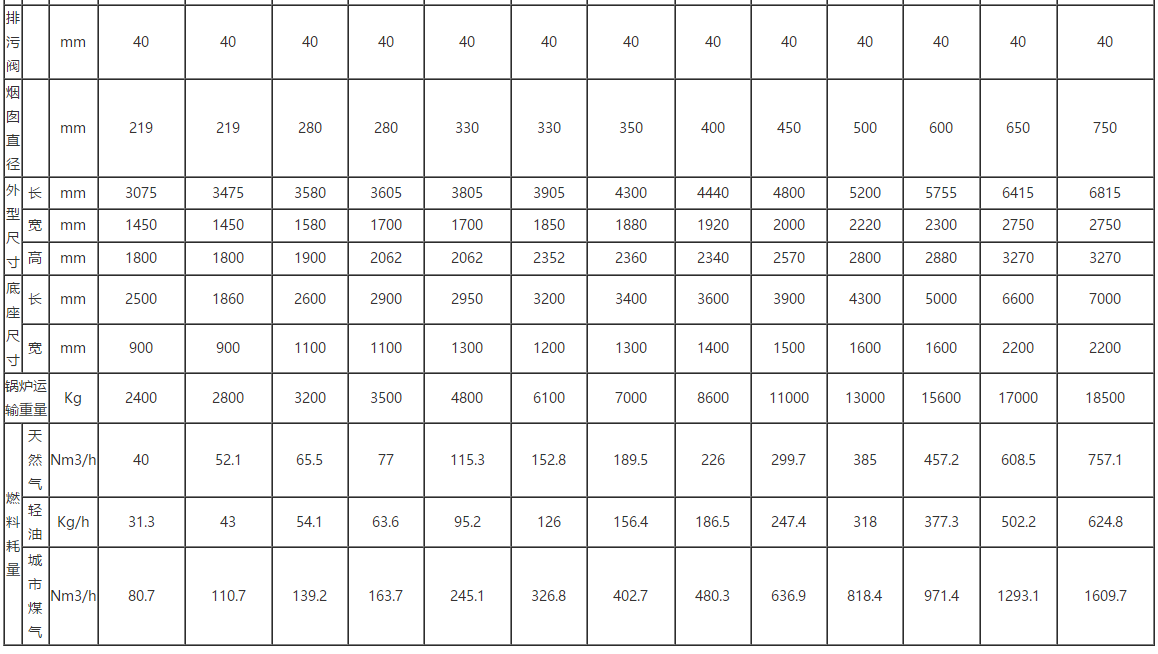

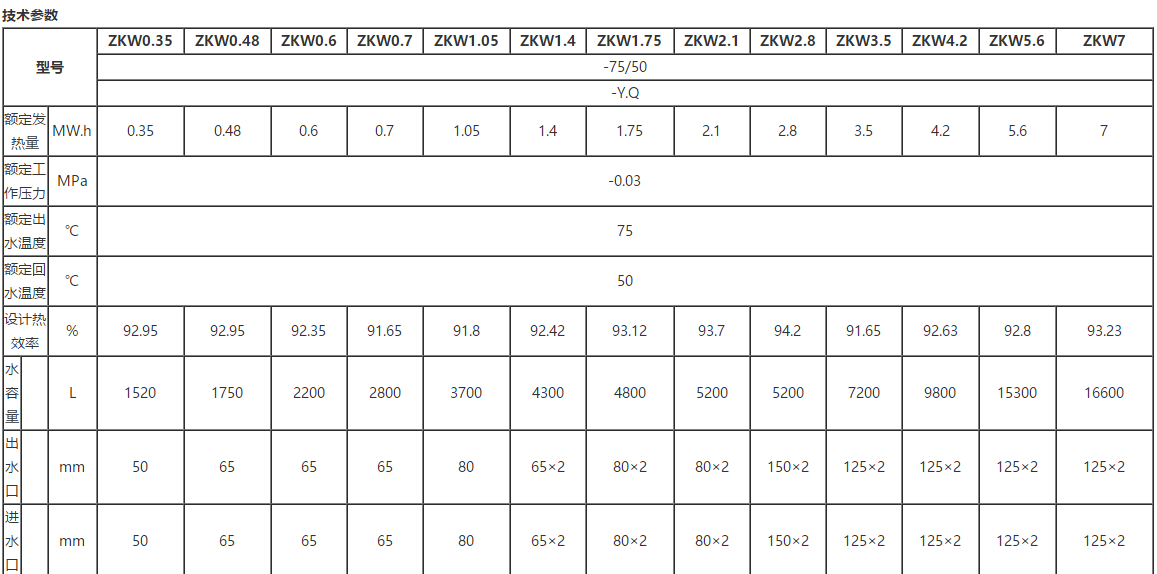

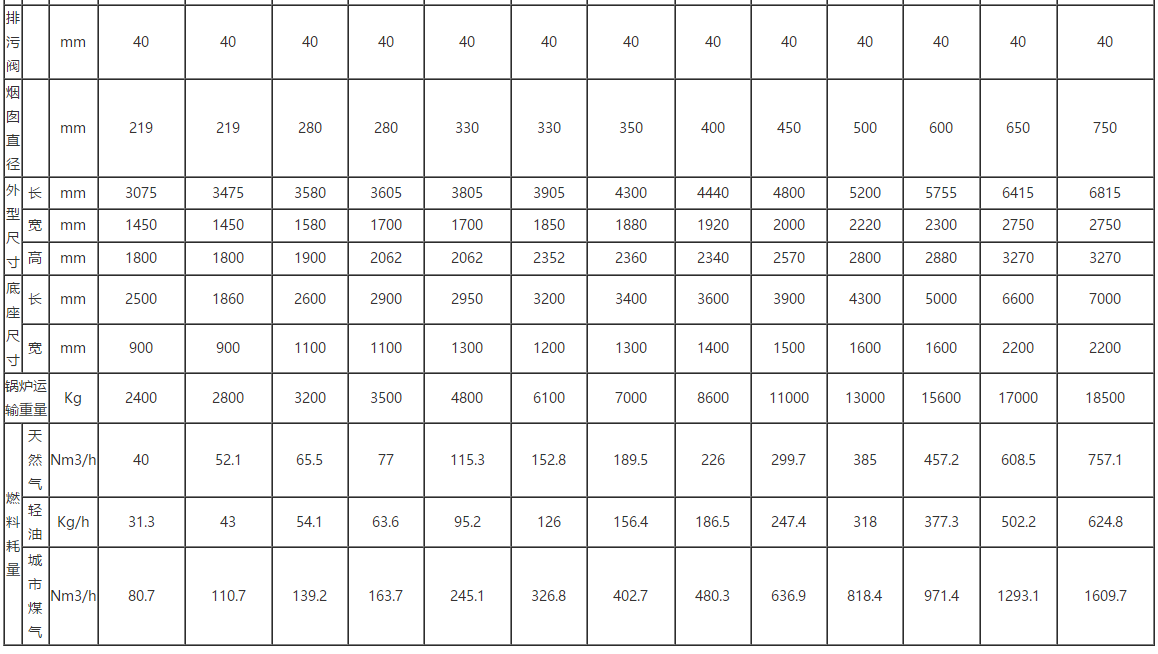

Product parameters

Remark:

1. All the above values are based on the low calorific value of natural gas (LNG) 8,400kcal/Nm³, city gas (CG) low calorific value 4,000kcal/Nm³, coke oven gas low calorific value 4,200kcal/Nm³, diesel low calorific value 10,200kcal /kg, methanol low calorific value 4650kcal/kg is the standard calculation.

2. According to user needs, our company can provide other special types of boilers.

Next:Nothing