Product details

Biomass fuel boiler specifically refers to a combination of biomass semi-gasification automatic control burner and special boiler. The biomass burner is mainly developed for the needs of mining and slow heating. It uses the abundant corn stalks and other crop stalks as raw materials, and is pressed into pellet fuel with regular shape and uniform size by molding equipment. The incinerator efficiently converts it into heat energy, and the heat generated by the incineration is absorbed by the circulating water in the boiler.

Biomass fuel boilers save 75% of the combustion cost compared to electric boilers, 60% compared to oil-fired boilers, 50% compared to natural gas boilers, and 40% compared to liquefied gas, with zero pollution.

The liner of the biomass burner is made of zirconium-silicon crystals, which are made of high-pressure casting and then fired in a high-temperature furnace. It needs to be fired at a temperature above 1000 °C for three days without loose pores. It is a biomass semi-gasification automatic control burner , Biomass pyrolysis burners that use biomass particles, wood chips, wood powder, sawdust and other organic biomass as fuel are generally divided into two types: air-cooled biomass burners and water-cooled biomass burners.

1. Main features

The biomass fuel special boiler adopts a horizontal wet-back three-return structure. The main body structure layout is professionally designed according to the characteristics of fuel combustion. The furnace and smoke pipes are of special structure, with large heating area, good heat transfer effect, good cooling conditions, and sufficient fuel combustion in the furnace. The boiler is specially designed with explosion-proof and ash cleaning ports, with high safety factor. , easy to operate. The smoke box door adopts the company's patented design to isolate smoke and heat insulation, which not only improves the thermal efficiency of the boiler but also facilitates opening. The boiler interface matches the biomass burner interface, and the installation is fast and convenient.

The environmental protection benefits are obvious: using renewable biomass energy as fuel to achieve sustainable use of energy. Using high-temperature staged combustion technology, the emission of NOX, SO2 and dust in the flue gas is low, and it is a substitute for coal-fired, oil (gas) boilers, and electric heating boilers.

No discharge of tar, waste water and other wastes: using high-temperature pyrolysis combustion technology, tar is directly burned in the form of gas, which solves the technical problem of high tar content in biomass gasification and avoids the secondary pollution of water quality caused by washing tar.

High heating temperature: The combustion technology adopts secondary air distribution, and the furnace is pressed at 500-700mm water column to ensure normal fluidization in the jet area. Continuous feeding and continuous production, stable flame, high temperature section temperature up to 1300 ℃, widely used in industry.

Low investment and operating costs: The biomass combustion mechanism is reasonably designed, and the transformation cost is low when used in various equipment. During operation, the heating cost is reduced by more than 60% compared with the oil-fired boiler, and the heating cost of the gas-fired boiler is reduced by more than 40%. , The choice of energy saving and environmental protection transformation and replacement of gas furnace .

Simple operation and convenient maintenance: the use of frequency conversion automatic feeding, wind removal of ash, simple operation, small workload, single person on duty, biomass boiler is the choice of the majority of boiler companies.

Wide range of fuel sources: The burner uses wood and sawdust particles as raw materials, with high calorific value, and avoids the occurrence of coking of straw particles.

2. Technical background

With the tense energy situation such as electricity shortage, oil shortage, rising electricity prices, gas prices and oil prices, as well as the increasingly serious environmental pollution problems, various industries have begun to gradually increase their awareness of the use of renewable energy, among which the use of biomass energy is The current practical solution. Biomass is the material existing on the earth, which includes all animals, plants and microorganisms and many organic matters derived, excreted and metabolized from these living substances. All kinds of biomass have a certain amount of energy. Biomass is the energy produced by biomass as a carrier. Biomass energy is a form of energy in which solar energy is stored in organisms in the form of chemical energy, directly or indirectly derived from photosynthesis of plants. The energy consumed by plants on the earth for photosynthesis accounts for 0.2% of the total radiation that the sun irradiates to the earth. Although this proportion is not large, the energy consumed by photosynthesis is 40 times the total energy consumption of human beings today. It can be seen that biomass energy is a huge energy source.

3. Purpose of the invention

The purpose of the invention is to overcome the disadvantages of low combustion efficiency, unstable combustion, insufficient and even harmful components when these biomasses are burned in conventional boilers, causing secondary pollution and low degree of automation. A special boiler that can effectively improve combustion efficiency.

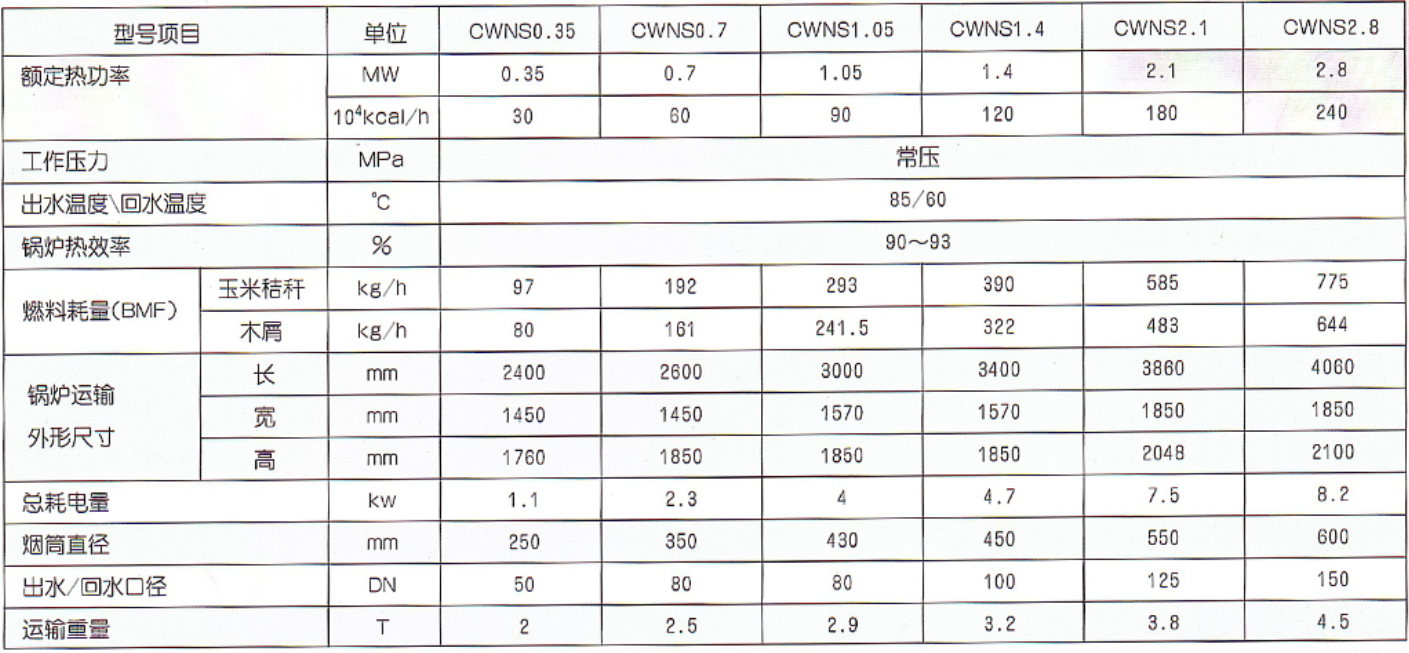

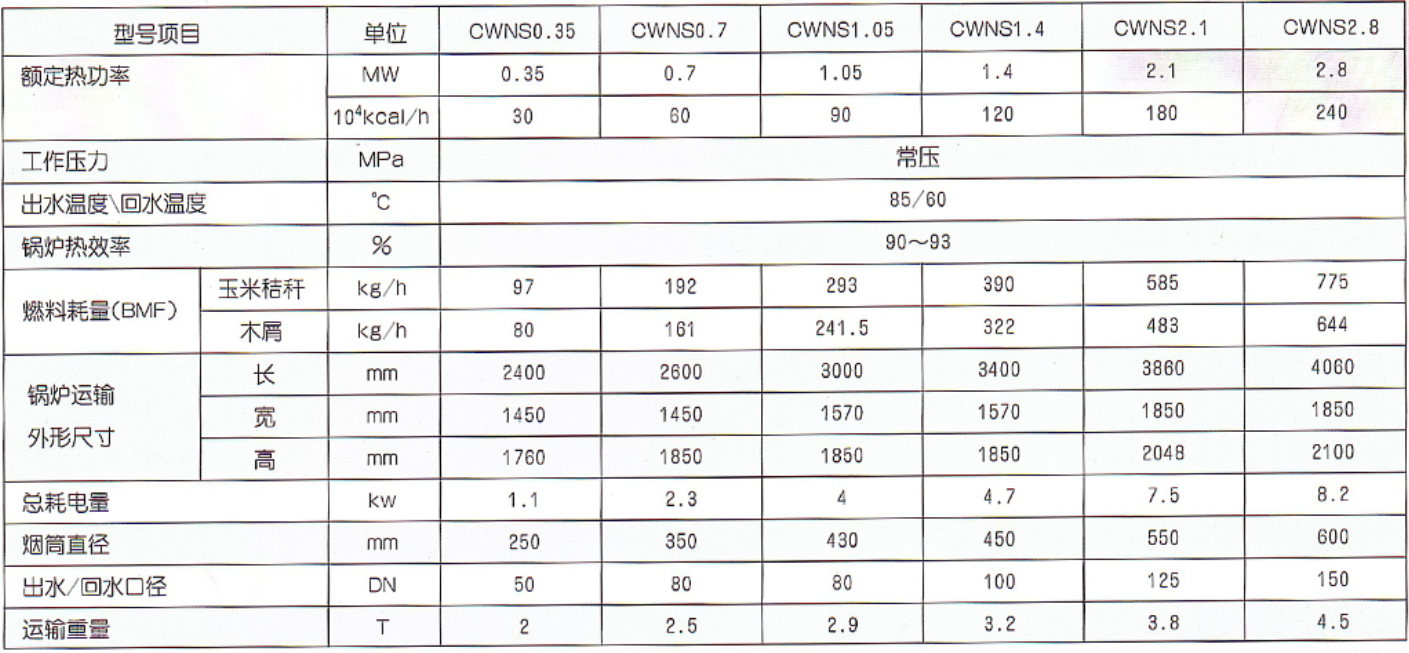

Product parameters

technical parameter